Casting nozzle

Keywords:

Classification:

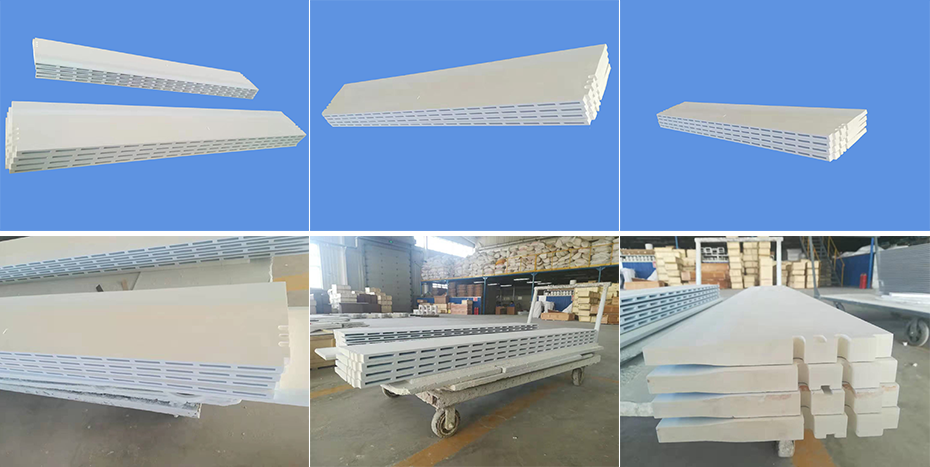

Product Details

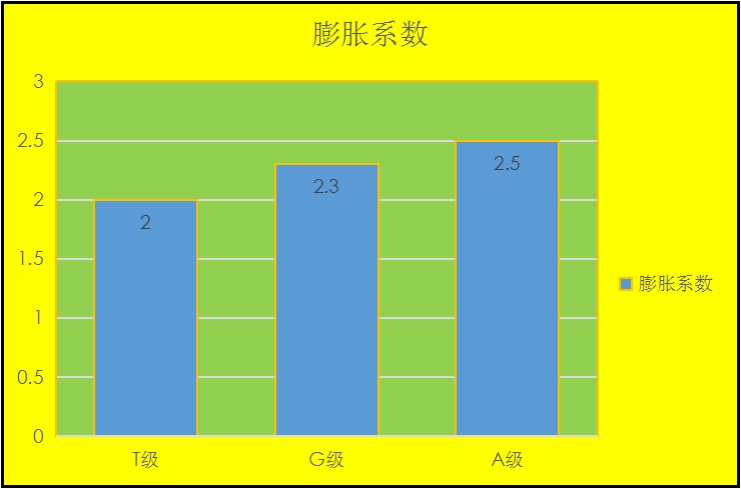

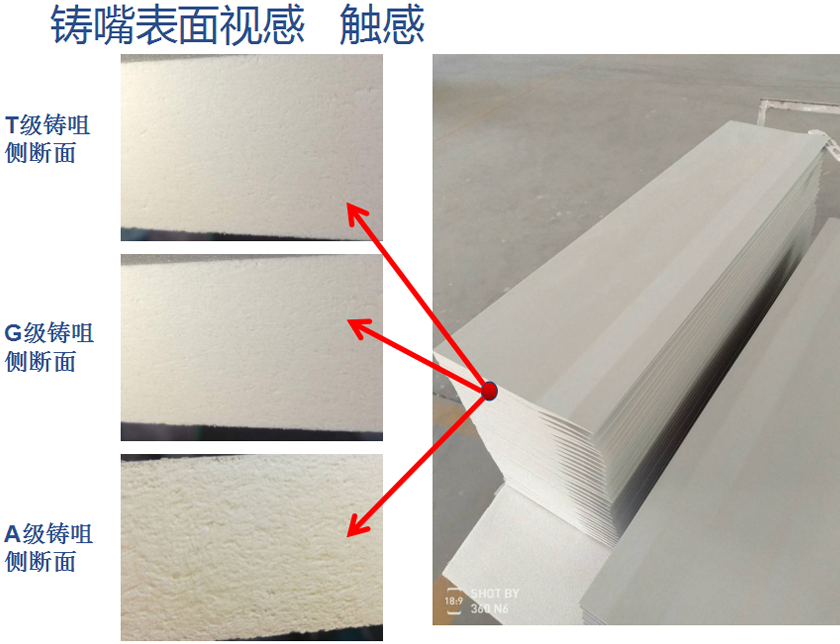

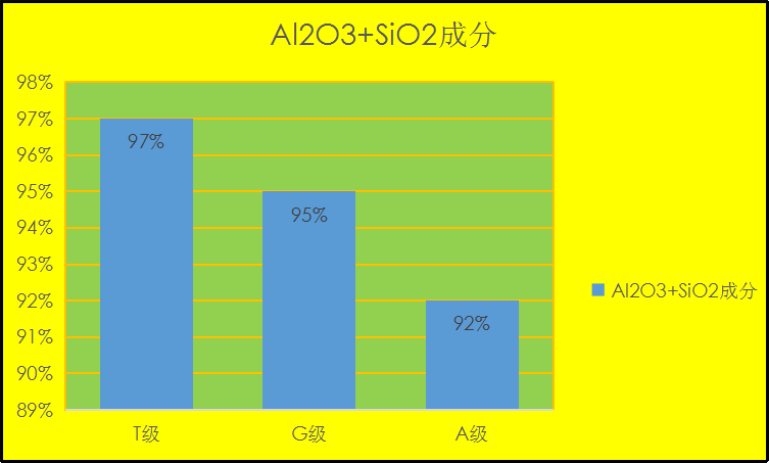

The roughness of the three-level casting nozzle is different at the surface appearance and cross section. The surface of the T-level casting nozzle is free of dust when rubbing with the palm of the hand. Dust will fall to different degrees below the T-level. The structure of the T-level casting nozzle of the cross section is tight. The following levels become rough step by step and loose. The raw materials used for Class A, Class G, Class T casting nozzles are different. Class A casting nozzles use natural hard clay clinker as raw materials, with fiber Al2O3 content ≥ 45% and harmful impurity content of 3% ~ 4%. Fiber use temperature 1000 ℃. The G-grade casting nozzle adopts high purity aluminum silicate fiber, and uses the synthetic material of industrial alumina powder and silica powder as raw material to make the harmful impurity content <1%, which not only uses the temperature higher than that of ordinary aluminum silicate fiber, but also applies to reducing atmosphere. Fiber use temperature 1100 ℃. T grade casting nozzle adopts high alumina fiber: industrial alumina powder and silica powder composite material as raw material. Fiber Al2O3 content ≥ 55%, harmful impurity content <1%. Due to the high content of Al2O3 in the fiber, and the ratio of Al2O3 to SiO2 in the fiber is close to the mullite composition, the amount of cristobalite crystallization is reduced, thereby improving the heat resistance and thermal vibration resistance of the fiber. Fiber use temperature 1200 ℃.

Main production process difference

Different raw materials used for Class A, Class G, Class T casting nozzle

Class A casting nozzle is made of natural hard clay clinker, with fiber Al2O3 content ≥ 45% and harmful impurity content of 3% ~ 4%. Fiber use temperature 1000 ℃.

The G-grade casting nozzle adopts high purity aluminum silicate fiber, and uses the synthetic material of industrial alumina powder and silica powder as raw material to make the harmful impurity content <1%, which not only uses the temperature higher than that of ordinary aluminum silicate fiber, but also applies to reducing atmosphere. Fiber use temperature 1100 ℃.

T grade casting nozzle adopts high alumina fiber: industrial alumina powder and silica powder composite material as raw material. Fiber Al2O3 content ≥ 55%, harmful impurity content <1%. Due to the high content of Al2O3 in the fiber, and the ratio of Al2O3 to SiO2 in the fiber is close to the mullite composition, the amount of cristobalite crystallization is reduced, thereby improving the heat resistance and thermal vibration resistance of the fiber. Fiber use temperature 1200 ℃.

Our company's new casting nozzle trial will use better materials.

Chromium-containing aluminum silicate fiber: 3% to 6% chromium oxide is added to the high-purity aluminum silicate fiber composite material to inhibit the crystallization change of amorphous fiber under heating conditions, so it is also called chromium stabilized fiber. Fiber use temperature 1200 ℃.

Zirconium-containing aluminum silicate fiber: zircon sand is added to the synthetic raw materials of alumina powder and silica powder to make the ZrO2 content in the fiber reach 12% ~ 15%. The fiber use temperature was increased to 1300°C.

Different production process

Class A and G casting nozzles adopt water vacuum suction filtration and secondary glue injection molding method with a glue capacity of%. Its additives, high temperature binder content, press pressure and holding time are lower than the T-grade casting nozzle.

The T-grade casting nozzle adopts pure glue suction and filtration, one-time mechanical forming method, with high glue capacity, reducing the production error of multiple processes, the content of additives and high-temperature adhesive, and the production pressure is better than that of ordinary casting nozzle.

The main application of casting nozzle at all levels

T-grade double zero foil electronic aluminum foil and other high-end products

G-class single and double zero foil, air conditioning foil, PS board base and other products with higher board surface requirements

Class A cable tape, packaging foil, pharmaceutical foil, decorative board, etc

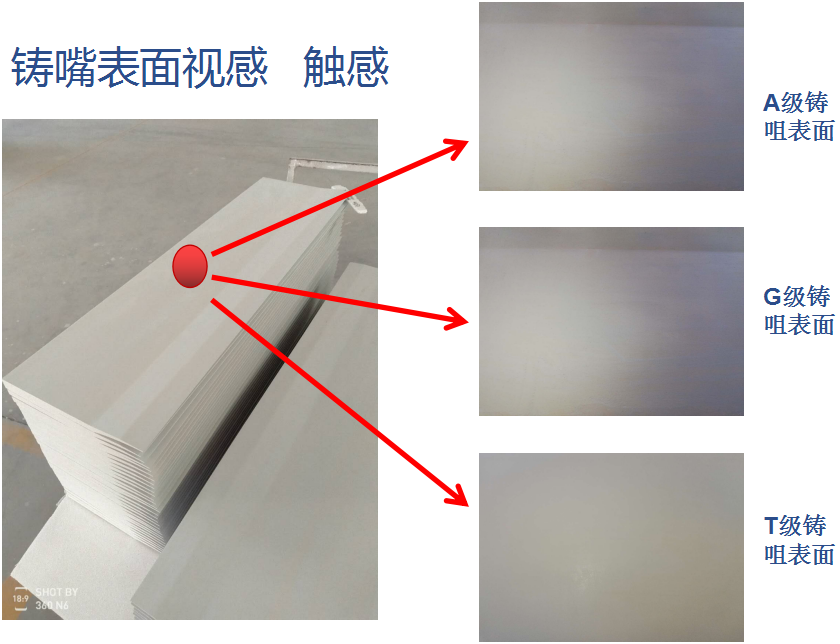

Surface visual feeling of casting mouth

The roughness of the three-level casting nozzle is different at the surface appearance and cross section. The surface of the T-level casting nozzle is free of dust when rubbing with the palm of the hand. Dust will fall to different degrees below the T-level. The structure of the T-level casting nozzle of the cross section is tight. The following levels become rough step by step and loose.

Previous:

The next one:

Inquiry

Please fill in the information accurately and keep communication open. We will contact you as soon as possible

Related Products

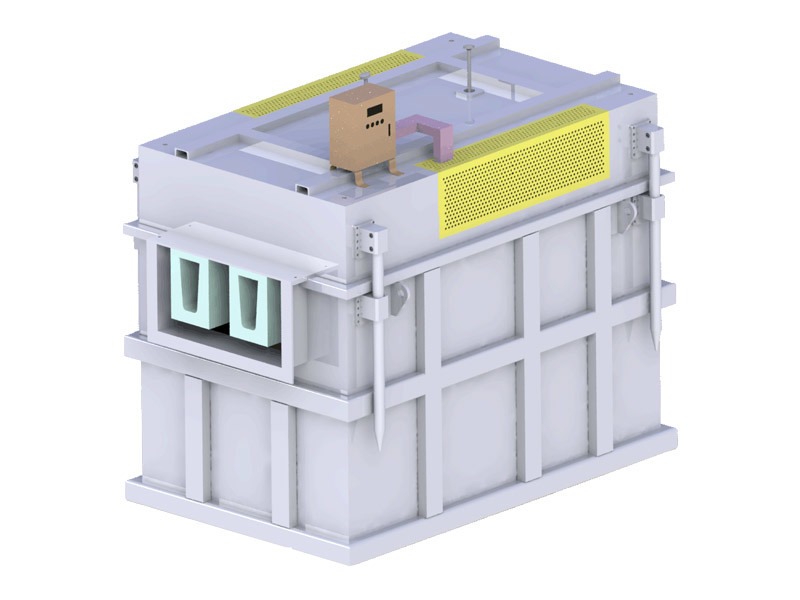

The Hongfeng degasser is designed with subsurface flow, matched with composite graphite rotor or silicon nitride rotor, heated by immersion heater, and can be equipped with permeable bricks according to the requirements of hydrogen removal. Different types and specifications of degassing equipment can be selected according to processing requirements.

Refractory materials refer to inorganic non-metallic materials with a refractoriness of not less than 1580 ℃, which are mainly used for structural materials of thermal equipment such as high-temperature furnaces, as well as materials of industrial high-temperature containers and components, and can withstand corresponding physical and chemical changes and mechanical effects.

Siliceous products, aluminum silicate products, magnesium products, dolomite products, chromium products, carbon products, zirconium products, etc.

The production process of non-sintered products.

Add:55 Jintai Middle Road, Jintai Development Zone, Dingxing County, Hebei Province, China

Tel:+86-13903127726

Quote Now

Solutions for Your Industry, Ready for Your Choice