Product

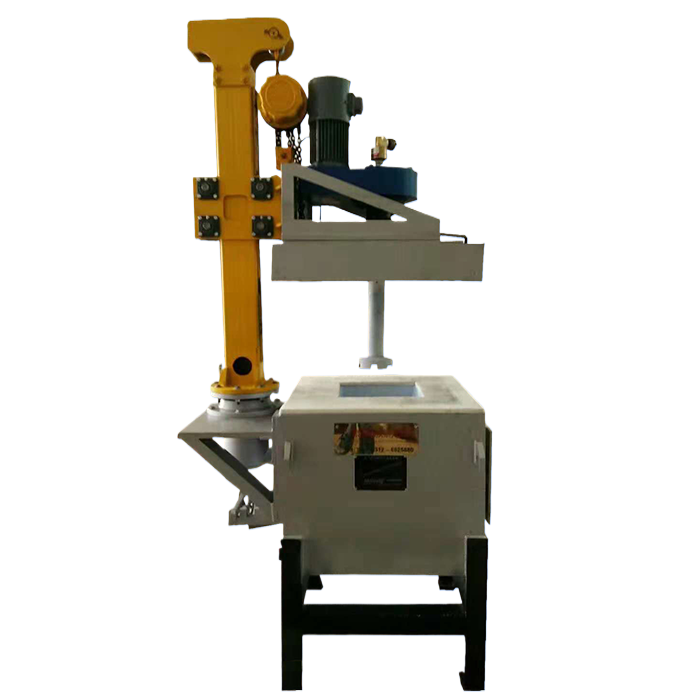

Hongfeng degasser adopts undercurrent design, supporting composite graphite rotor or silicon nitride rotor, heating by immersion heater, and can be selected according to dehydrogenation requirements. Different types and specifications of degassing equipment can be selected according to processing requirements.

Hongfeng degasser adopts undercurrent design, supporting composite graphite rotor or silicon nitride rotor, heating by immersion heater, and can be selected according to dehydrogenation requirements. Different types and specifications of degassing equipment can be selected according to processing requirements.

Hongfeng degasser adopts undercurrent design, supporting composite graphite rotor or silicon nitride rotor, heating by immersion heater, and can be selected according to dehydrogenation requirements. Different types and specifications of degassing equipment can be selected according to processing requirements.

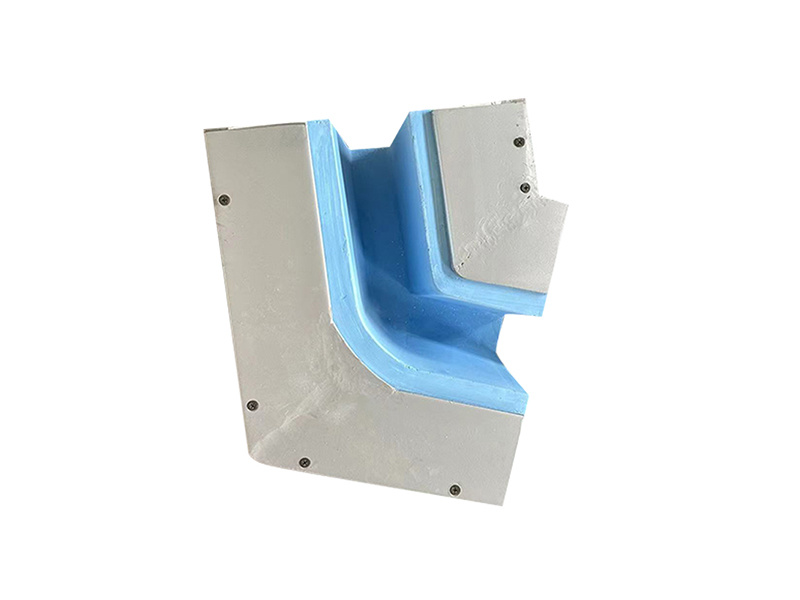

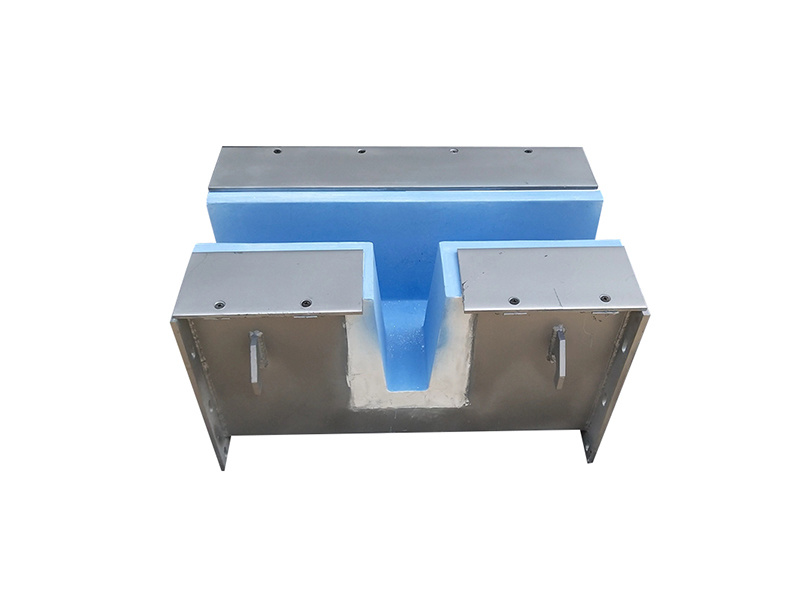

In the smelting process of steel and non-ferrous metals, it is used for the manufacture and maintenance of furnaces, furnace bottoms, furnace doors and other parts.

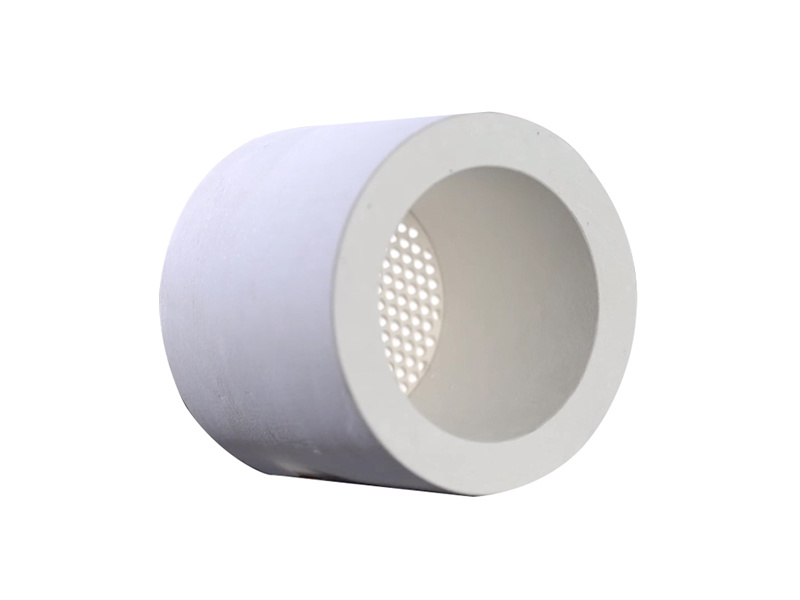

Silicon nitride protection tube

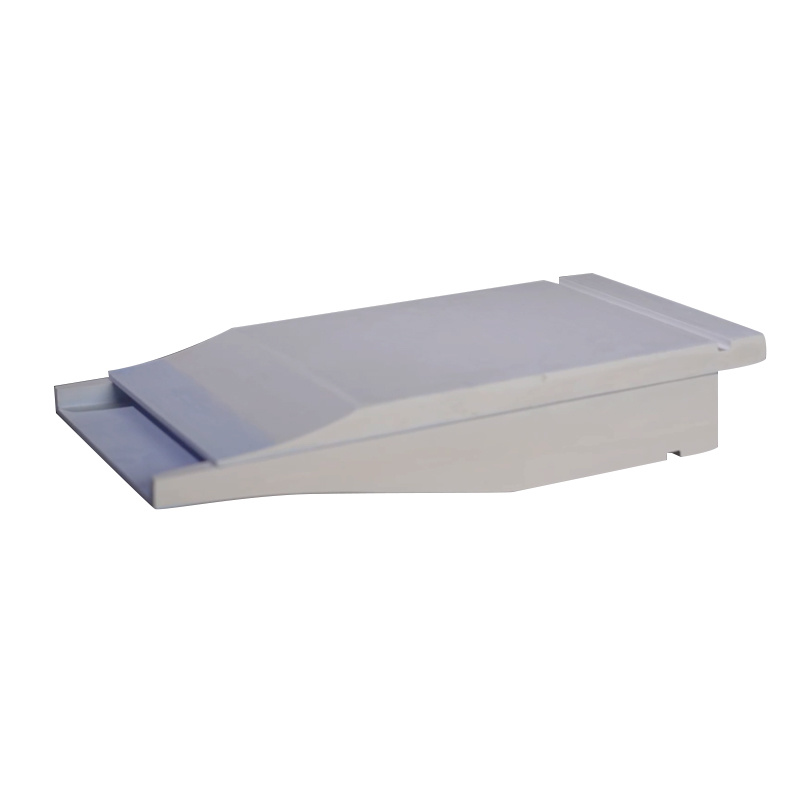

Refractory materials refer to inorganic non-metallic materials with a refractoriness of not less than 1580 ℃, which are mainly used for structural materials of thermal equipment such as high-temperature furnaces.

With alumina, magnesia and silicate as the main components, it has good heat resistance and thermal shock resistance, and is widely used in furnace structure.

Add:55 Jintai Middle Road, Jintai Development Zone, Dingxing County, Hebei Province, China

Tel:+86-13903127726

Quote Now

Solutions for Your Industry, Ready for Your Choice