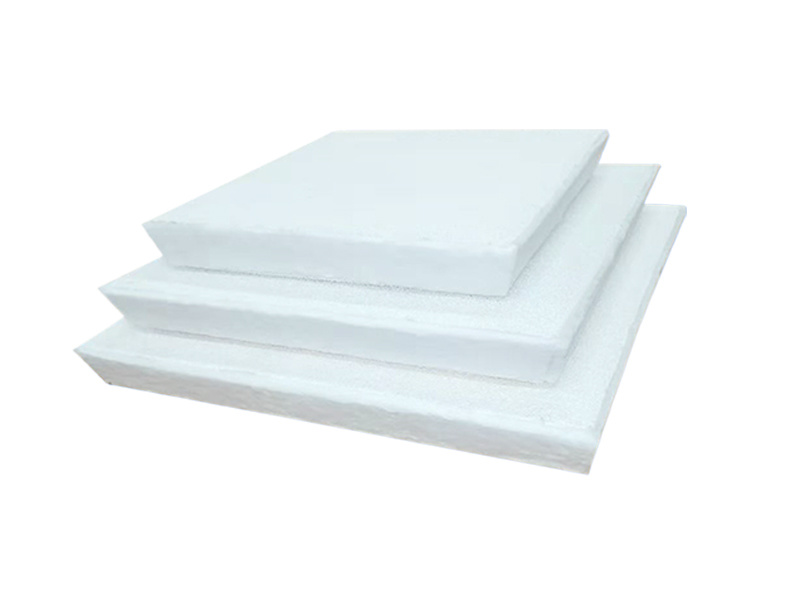

Refractory product

The production process of refractory materials includes the steps of raw material preparation, batching, mixing, molding, drying, firing and inspection.

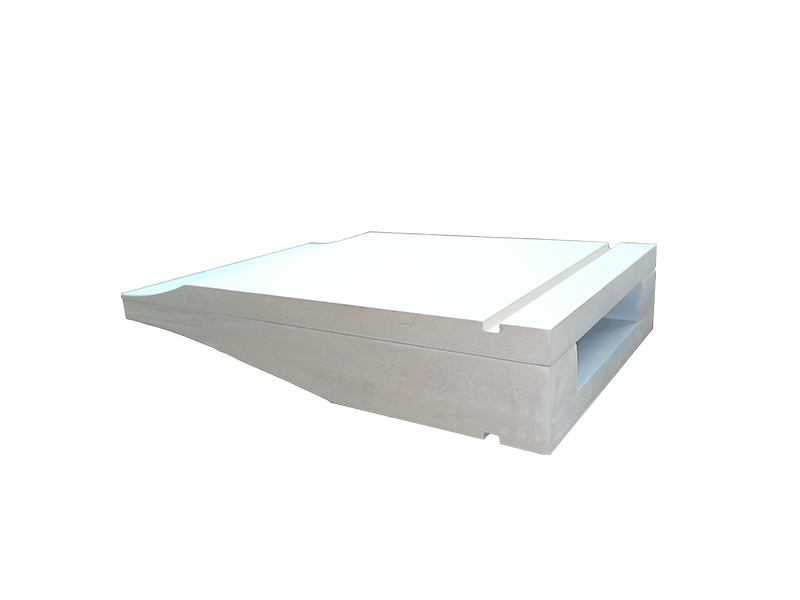

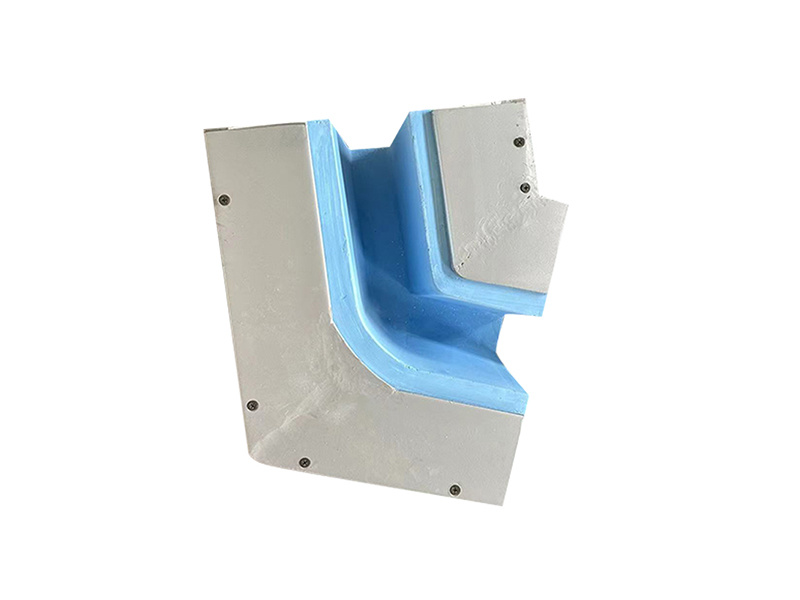

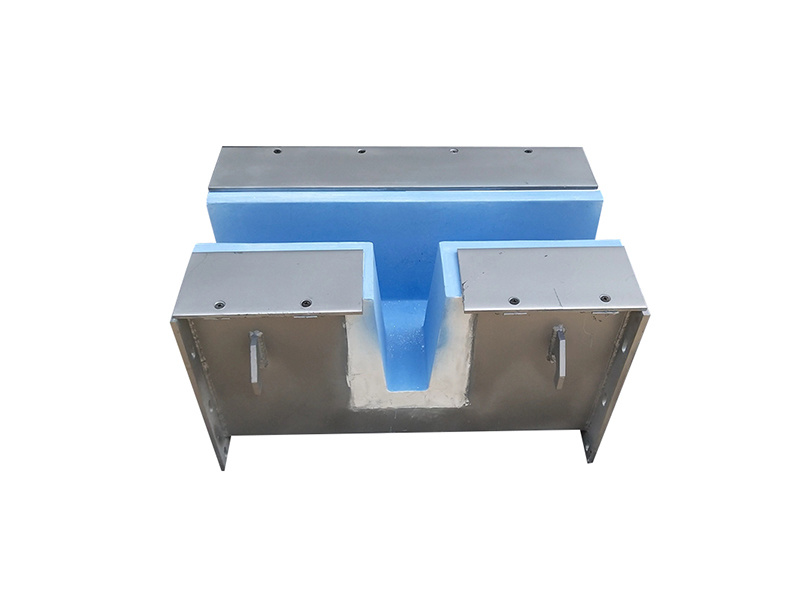

The roughness of the three-stage casting nozzle differs in surface appearance and section. There is no dust on the surface of the T-level casting nozzle with the palm of your hand, and different degrees of dust fall below the T-level.

The roughness of the three-stage casting nozzle differs in surface appearance and section. There is no dust on the surface of the T-level casting nozzle with the palm of your hand, and different degrees of dust fall below the T-level.

The roughness of the three-stage casting nozzle differs in surface appearance and section. There is no dust on the surface of the T-level casting nozzle with the palm of your hand, and different degrees of dust fall below the T-level.

The roughness of the three-stage casting nozzle differs in surface appearance and section. There is no dust on the surface of the T-level casting nozzle with the palm of your hand, and different degrees of dust fall below the T-level.

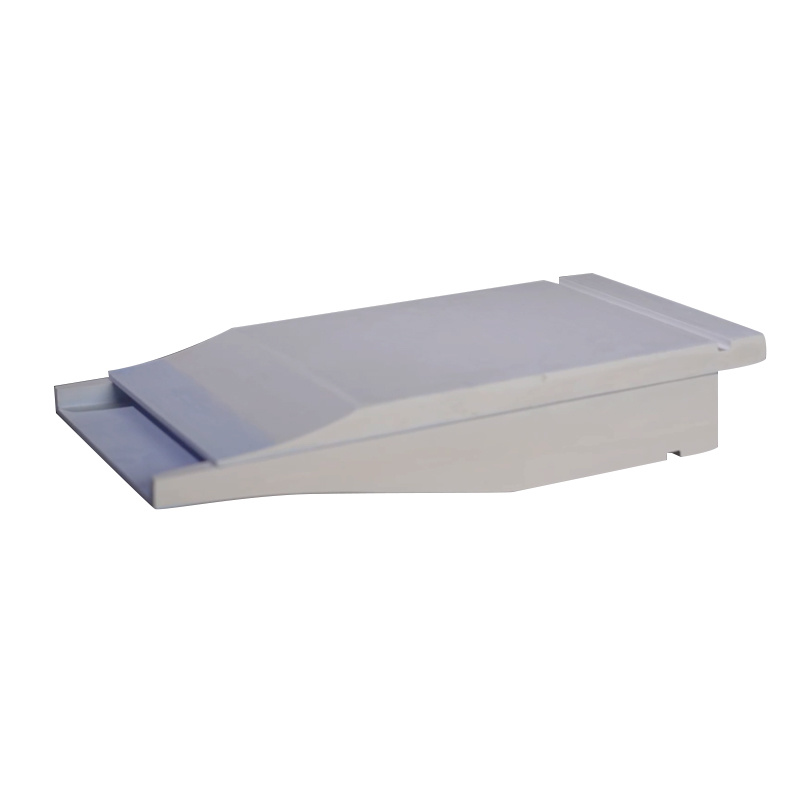

The roughness of the three-stage casting nozzle differs in surface appearance and section. There is no dust on the surface of the T-level casting nozzle with the palm of your hand, and different degrees of dust fall below the T-level.

The roughness of the three-stage casting nozzle differs in surface appearance and section. There is no dust on the surface of the T-level casting nozzle with the palm of your hand, and different degrees of dust fall below the T-level.

The roughness of the three-stage casting nozzle differs in surface appearance and section. There is no dust on the surface of the T-level casting nozzle with the palm of your hand, and different degrees of dust fall below the T-level.

Add:55 Jintai Middle Road, Jintai Development Zone, Dingxing County, Hebei Province, China

Tel:+86-13903127726

Quote Now

Solutions for Your Industry, Ready for Your Choice